Home » FAQ

There’s no limit in stripping the screens because there’s no effect from water on the surface of the nickel. If the screens are handled correctly in production then screens can be re-used multiple times.

Yes. The only problem occurs if the emulsion penetrates inside the nickel screen. The water stripping can only remove emulsion from the outside of the screen.

It is a mixture of toxic chemicals like Methylene Chloride, Dichloromethane Chloride, Formic Acid and Phenol. All of these chemicals have already been banned in the international community.

– Your workers don’t have to work with highly toxic chemicals anymore.

– Saving the environment and groundwater for future generations.

– Easier and cheaper water treatment.

– The screens will not be damaged by chemicals and can be re-used ,multiple times

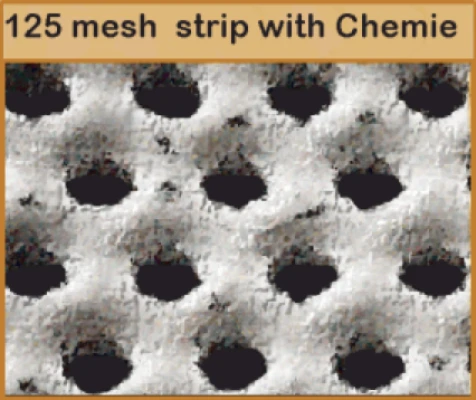

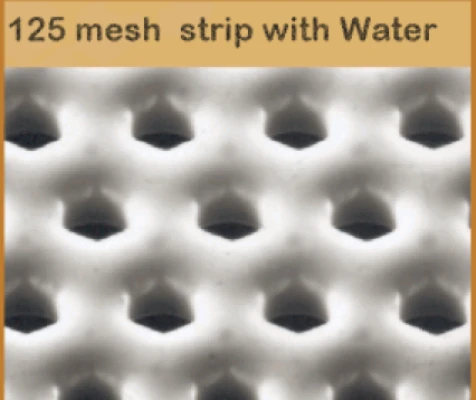

– No changes in the open area of the screen.

– You can also strip high mesh nickel screens (155,165,185,195), along with special effect screens for glitter etc. saving on these expensive screens as they can be re-used multiple times.

It strongly depends on which kind of dyestuff you’re printing and what kind of screen supplier you’re using. It also depends on what the squeegee type is (blade or magnet). In most cases a single new screen from an European supplier will last approx.. 100 000 meters of printing length on average.

Firstly, the screen is loaded on the brush holders. Screens can be loaded with end rings and taping or without. After that, the NovaJet will remove the tape and the end ring glue without any problem. In typically 10 minutes (depending on screen coating), a 640 mm diameter screen is stripped with perfect results, without damaging the nickel surface, a problem typical for laser strippers and systems using a nozzle block. The additional benefit of the NovaJet water stripping machine is that we are utilizing a nozzle bar with equal pressure on all surfaces to ensure the screens are well cleaned.

In the year 2000, a co-operation between Inter Silk Screen Co., Ltd and CST GmbH Germany was established to open a new company named Nova Inter Tech Co., Ltd.